Before power tools became commonplace on shop floors, job sites, and rail yards, skilled tradesmen relied on precision, technique, and a whole lot of muscle. And when it came to maintaining the iron horses of early American railroads, there was one unsung hero in every mechanic’s tool roll: the back-out punch.

A Tool Born for the Rails

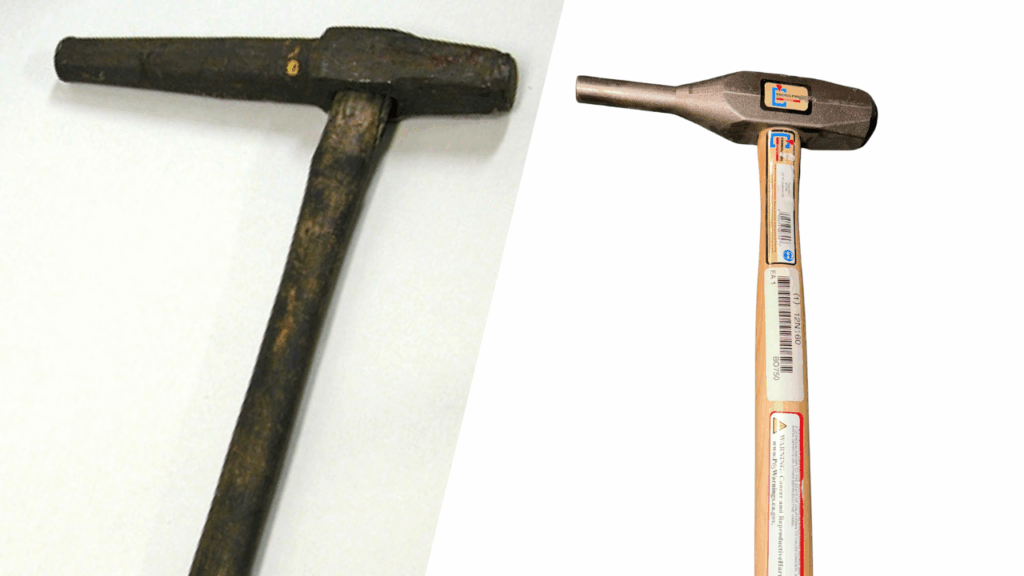

The back-out punch featured in the photo below was forged sometime between 1900 and 1950. Though humble in appearance, it played a vital role in the demanding world of steam locomotive maintenance. This particular tool was used in Salisbury, North Carolina, a key site for rail repair during the steam era.

Its job? Simple—but crucial. After a bolt or rivet head was cut off, this tool was struck with a hammer to drive out the remaining shank. In the days before high-torque pneumatic tools or cordless drills, this was how you got the job done. It was an essential part of inspections, overhauls, and everything in between.

These punches were commonly used in roundhouses — circular or semicircular engine sheds used for servicing locomotives — and in centralized repair facilities known as “back shops,” where heavier and more complex repairs took place. These buildings weren’t just functional spaces. They were the heart of America’s railroad infrastructure — and tools like this one kept the beat going.

Legacy That Lives On

Fast forward to today, and back-out punches are still holding strong.

While the tools of the trade have certainly evolved — we now have battery-powered impact guns, hydraulic pullers, and advanced CNC machining — some jobs still demand the direct force and control only a manual punch can provide.

Enter: the modern Council Tool 3/4” Back-Out Punch — a durable, American-made version built with high-strength steel and designed to withstand the daily grind in:

- Railroads

- Heavy equipment repair

- Fabrication shops

- Construction and field service

Whether you’re knocking out corroded bolts in an engine mount or dismantling machinery where space and leverage are limited, these tools remain relevant — and often preferred.

More Than Just a Tool

The back-out punch is a reminder of an era when tools had to be tough, simple, and field-serviceable. In many ways, it’s a bridge between then and now — proving that some designs don’t need to be reinvented.

And more than anything, it’s a tribute to the generations of tradesmen and women who knew how to work smart, strike hard, and fix what needed fixing — without relying on batteries or buttons.

📸 Photo 1: Early 20th-century back-out punch, part of a collection used for inspecting and repairing steam locomotives in Salisbury, NC.

📸 Photo 2: Council Tool’s modern 3/4” back-out punch, proudly made in the USA.

📍 Tool Credit: National Museum of American History – Behring Center

#ForgingFriday #Trades #Railroads #ToolHistory #BackOutPunch #AmericanMade #FabricationTools #Manufacturing #SteamEra #HandTools #SkilledTrades #IndustrialHeritage #CouncilTool #ThenAndNow #MadeInUSA